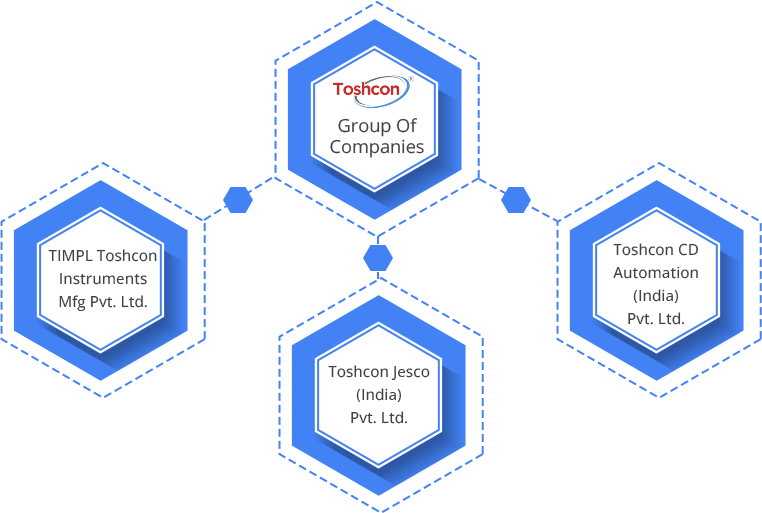

- About Us

- Products & Solutions

-

Analytical Instruments

Digital Meters

Portable Instruments

Benchtop Instruments

Spares & Accessories

Stand

Laboratory & Industrial Electrodes / Sensors

Laboratory Sensors - pH / Redox/ Conductivity/ Dissolved oxygen & ISE

Industrial Electrodes / Sensors

Spares & Accessories

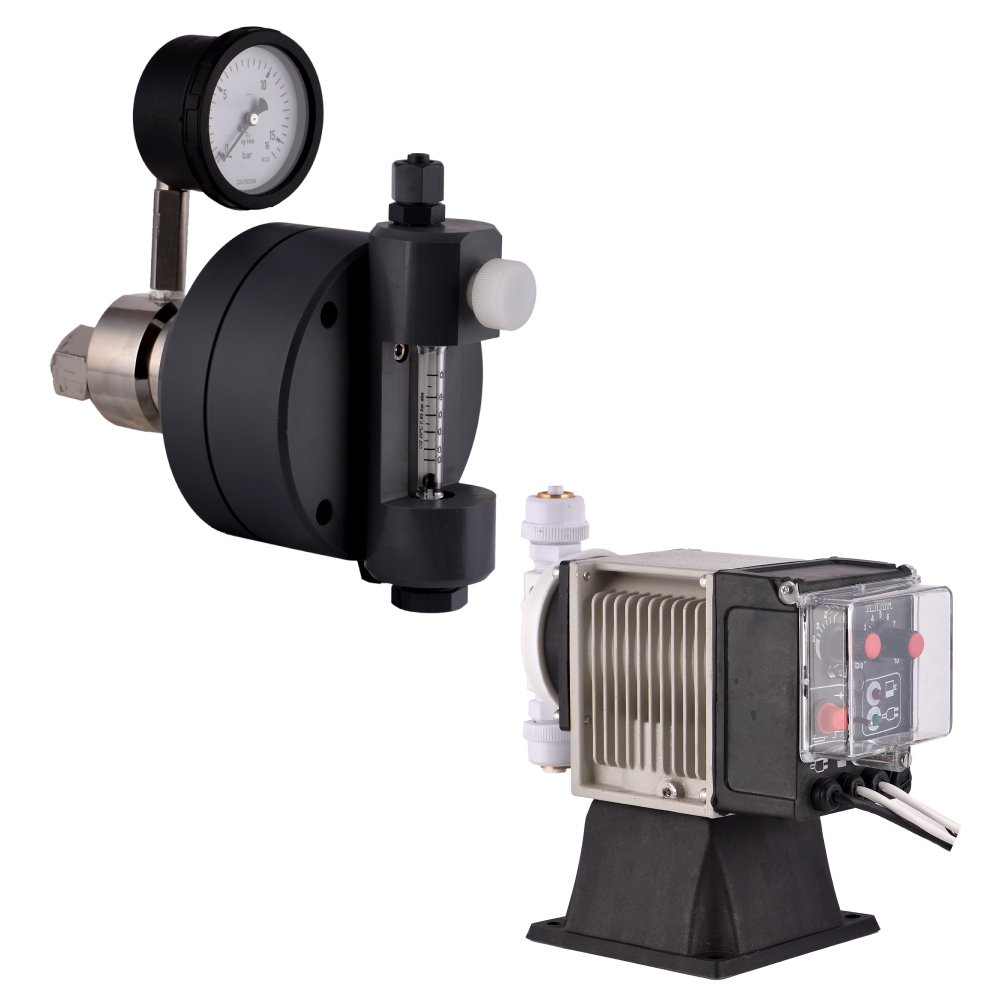

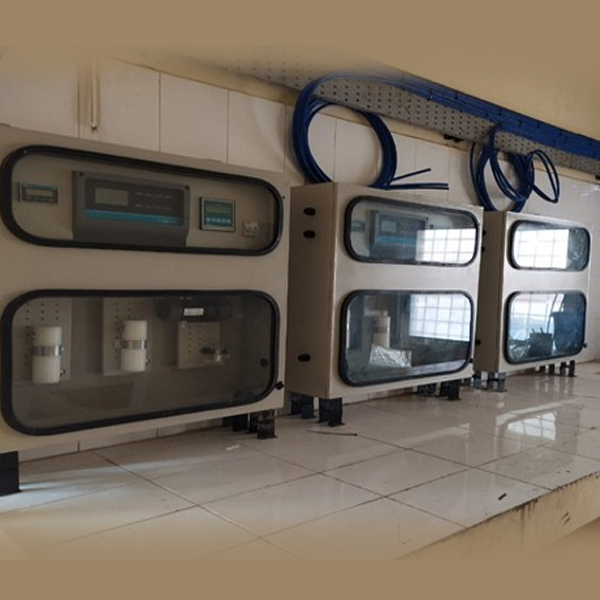

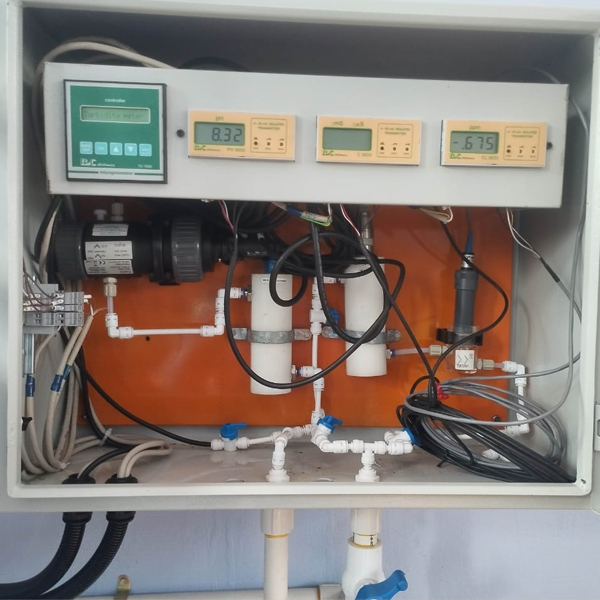

Online Water Quaity Analysers Instruments

Transmitters

Analysers / Controllers

Analog / Digital Output Probes & Sensors

Flow Cells, Enclosures & Accessories

-

- Services & Support

- New Launch

- Career

- Events & Exhibitions

- Contact Us

-

75+

Years of Experience

45000+

Clients

350+

Employees

30+

Countries Served

75+

Years of Experience

Years of Experience

45000+

Clients

Clients

350+

Employees

Employees

30+

Countries Served

Countries Served

SOME OF OUR ESTEEMED CLIENTS

Our more than 75 years long noteworthy existence in the market in itself is a proof of satisfaction ...

Contact Us

| P.O. Gagwana - 305023, Distt. Ajmer (Raj.) India |

|

| info@toshcon.com support@toshcon.com |

|

| +91 9829112345 +91-145-2971131/2/3 |

© 2024 Toshcon. All rights reserved.

Privacy Policy | Terms & conditions

Site.jpg)

Tamilnadu Dosing System.jpg)

- Noida Site Chlorine Leak Absorption System.jpg)

.jpg)

Jawai Cluster Site.jpg)

- Site Safety Shower.jpg)

Site.jpg)

Site.jpg)